Factory making Sanitary Sewer Flow Monitoring - Dual-channel Transit-Time Clamp On Ultrasonic Flowmeter TF1100-DC – Lanry Detail:

Description

Features

Applications

Specificaitons

Principle

Dimensional

TF1100-DC Dual-channel Wall-mounted Transit Time Ultrasonic Flowmeter works on the transit-time method. The clamp-on ultrasonic transducers (sensors) are mounted on the external surface of the pipe for non-invasive and non-intrusive flow measurement of liquid and liquefied gasses in fully filled pipe. Two pairs of transducers are sufficient to cover the most common pipe diameter ranges. In addition, its optional thermal energy measurement capability makes it possible to carry out a complete analysis of thermal energy usage in any facility.

This flexible and easy to use flow meter is the ideal tool for the support of service and maintenance activities. It can also be used for the control or even for the temporary replacement of permanently installed meters.

Features

Data logger function.

Aluminum or Stainless steel SUS304 sensors for your optional.

Thermal energy measurement capability can be optional.

For commonly used pipe materials and diameters from 20mm to 6.0m.

Wide bi-directional flow range of 0.01 m/s to 15 m/s.

Applications

16.00

Normal

0

7.8 磅

0

2

false

false

false

EN-US

ZH-CN

X-NONE

/* Style Definitions */

table.MsoNormalTable

{mso-style-name:普通表格;

mso-tstyle-rowband-size:0;

mso-tstyle-colband-size:0;

mso-style-noshow:yes;

mso-style-priority:99;

mso-style-parent:”";

mso-padding-alt:0cm 5.4pt 0cm 5.4pt;

mso-para-margin:0cm;

mso-pagination:widow-orphan;

font-size:10.0pt;

font-family:”Times New Roman”,serif;}

● Service and maintenance

● Replacement of defective devices

● Support of commissioning process and installation

● Performance and efficiency measurement

- Evaluation and assessments

- Capacity measurement of pumps

- Monitoring of regulating valves

● Water and waste water industry – hot water, cooling water, potable water, sea water etc.)

● Petrochemical industry

● Chemical industry -chlorine, alcohol, acids, .thermal oils.etc

● Refrigeration and air conditioning systems

● Food , beverage and pharmaceutical industry

● Power supply- nuclear power plants, thermal & hydropower plants), heat energy boiler feed water.etc

● Metallurgy and mining applications

● Mechanical engineering and plant engineering-pipeline leak detection, inspection, tracking and collection.

Specifications

Transmitter:

|

Measurement principle |

Ultrasonic transit-time difference correlation principle |

|

Flow velocity range |

0.01 to 15 m/s, bi-directional |

|

Resolution |

0.1mm/s |

|

Repeatability |

0.15% of reading |

|

Accuracy |

±0.5% of reading at rates >0.3 m/s);±0.003 m/s of reading at rates<0.3 m/s |

|

Response time |

0.5s |

|

Sensitivity |

0.001m/s |

|

Damping of displayed value |

0-99s(selectable by user) |

|

Liquid Types Supported |

both clean and somewhat dirty liquids with turbidity <10000 ppm |

|

Power Supply |

AC: 85-265V DC: 24V/500mA |

|

Enclosure type |

Wall-mounted |

|

Degree of protection |

IP66 according to EN60529 |

|

Operating temperature |

-10℃ to +60℃ |

|

Housing material |

Fiberglass |

|

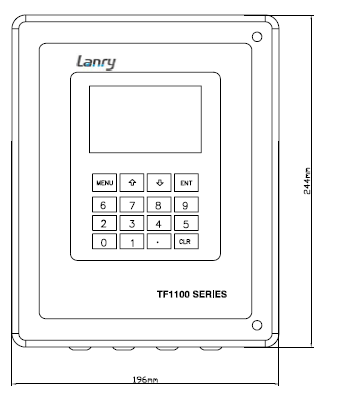

Display |

4.3’’ color LCD 5 lines display, 16 keys |

|

Units |

User Configured (English and Metric) |

|

Rate |

Rate and Velocity Display |

|

Totalized |

gallons, ft³, barrels, lbs, liters, m³,kg |

|

Thermal energy |

unit GJ,KWh can be optional |

|

Communication |

4~20mA(accuracy 0.1%),OCT, Relay, RS485 (Modbus),data logger |

|

Security |

Keypad lockout, system lockout |

|

Size |

244*196*114mm |

|

Weight |

2.4kg |

Transducer:

|

Degree of protection |

Standard IP65; IP67, IP68 can be optional |

|

Suited Liquid Temperature |

-35℃~200℃ |

|

Pipe diameter range |

20-50mm for type B, 40-4000mm for type A |

|

Transducer Size |

Type A 46(h)*31(w)*28(d)mm |

| Type B 40(h)*24(w)*22(d)mm | |

|

Material of transducer |

Aluminum or Stainless steel SUS304 |

|

Cable Length |

Std:10m |

|

Temperature Sensor |

Pt1000, 0 to 200℃, Clamp-on and Insertion type Accuracy: ±0.1% |

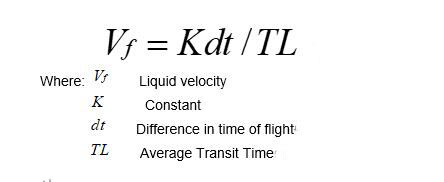

Principle of measurement

The TF1100 ultrasonic flow meter is designed to measure the fluid velocity of liquid within a closed pipe. The transducers are a non-invasive, clamp-on type, which will provide benefits of non-fouling operation and easy installation.

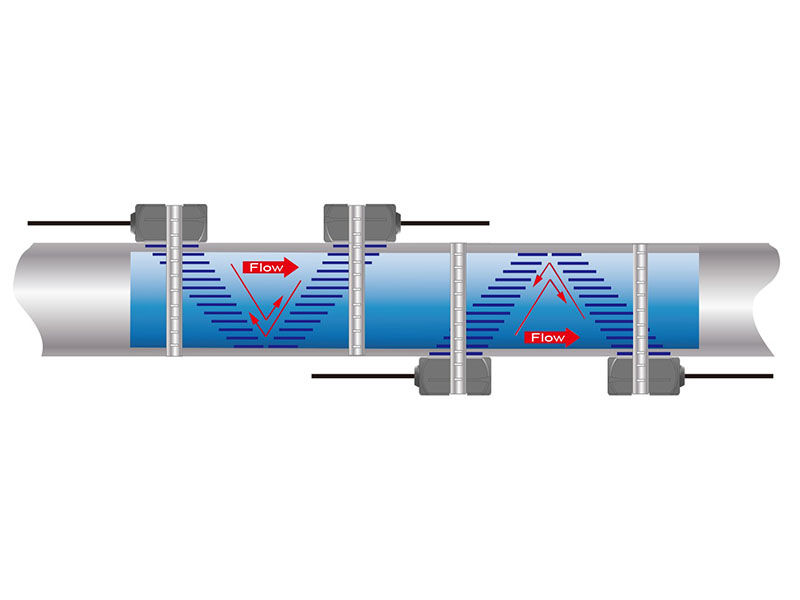

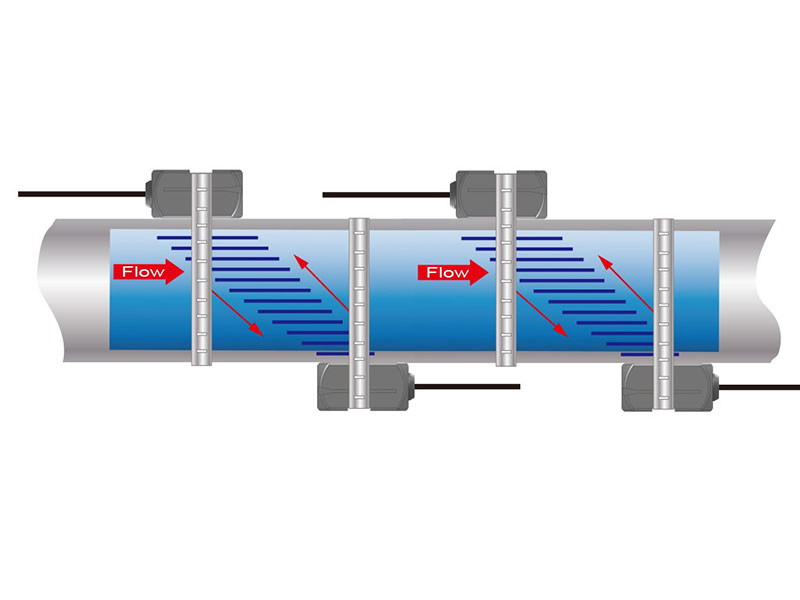

The TF1100 transit time flow meter utilizes two transducers that function as both ultrasonic transmitters and receivers. The transducers are clamped on the outside of a closed pipe at a specific distance from each other. The transducers can be mounted in V-method where the sound transverses the pipe twice, or W-method where the sound transverses the pipe four times, or in Z-method where the transducers are mounted on opposite sides of the pipe and the sound crosses the pipe once. This selection of the mounting method depends on pipe and liquid characteristics. The flow meter operates by alternately transmitting and receiving a frequency modulated burst of sound energy between the two transducers and measuring the transit time that it takes for sound to travel between the two transducers. The difference between the transit-time is directly and exactly related to the velocity of the liquid in the pipe, as shown in below Figure.

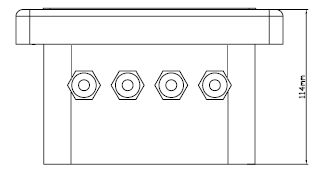

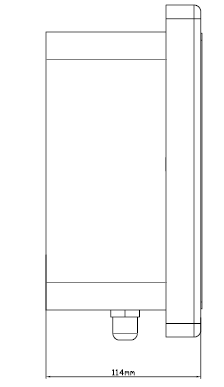

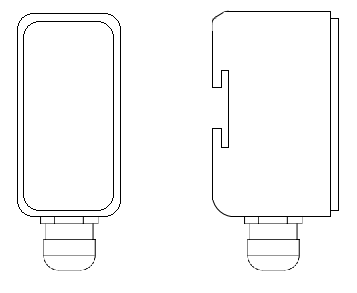

Dimensional Sketches

Transmitter:

Transducer:

B 40(h)*24(w)*22(d)mm}

A 46(h)*31(w)*28(d)mm

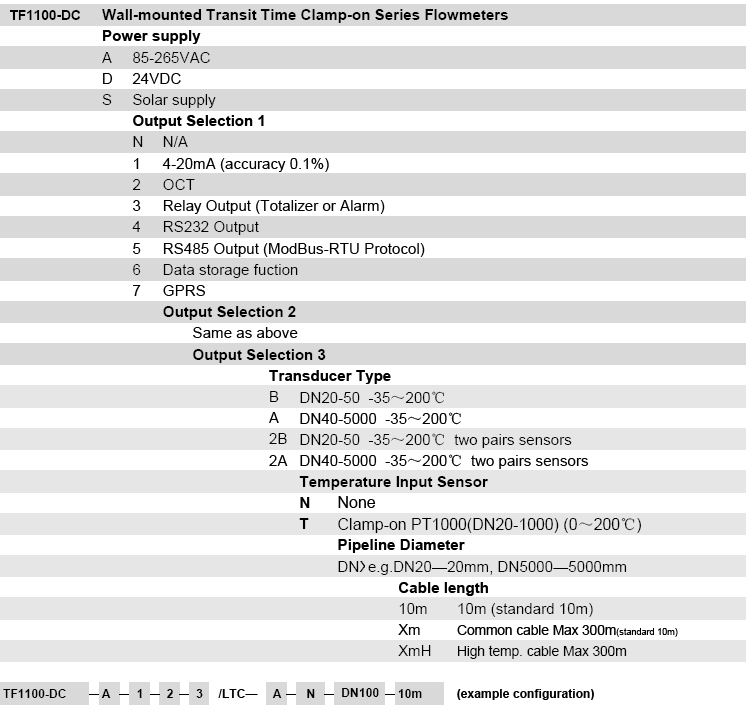

Configuration Code

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Factory making Sanitary Sewer Flow Monitoring - Dual-channel Transit-Time Clamp On Ultrasonic Flowmeter TF1100-DC – Lanry, The product will supply to all over the world, such as: Mombasa, Qatar, Guyana, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.